The following task uses the free lighting software, Relux, to perform a simple lighting calculation for a small office.

A CAD layout of the office is first uploaded into Relux. The CAD plan is a DWG file.

CAD plan imported into Relux

The room is then drawn by plotting the corners of the inside office walls. Once the room is drawn we can edit the height of the room. In this case, we are using a false ceiling height of 3 metres. We can then add room details, such as windows, doors and in this office, several structural pillars. If necessary, room furniture e.g. desks, computers, chairs etc. can be added. This will be detailed in a later exercise.

Once the room structure and furniture have finalised, luminaires can be added to the room. In Relux, this can be done in several ways: loading a new luminaire from a file stored on your computer or the built-in data base ReluxNet.

The luminaire chosen for this project is a square modular, recessed luminaire by Thorn Lighting (Chosen Luminaire), as there is an existing 600 x 600 mm ceiling grid already installed in the office, on which the new luminaires will be fixed. The Relux files are simply downloaded from the Thorn website and imported into Relux.

For an office of this type i.e. filling, copying etc. EN 12464-1 “Lighting of Indoor Workplaces” tells us that the minimum lux levels required is 300 lux (Zumtobel Lighting Handbook). If needed, we can edit the type of room within Relux, so that when the lighting calculations are performed, Relux will automatically compare the results to the standard required levels.

Luminaires are added to the room either manually, or by using the EasyLux procedure. The EasyLux procedure will automatically place luminaires within the room depending on your required lux level and luminaire suspension height. However, this function does not consider room objects, and will place luminaires that will clash with our structural pillars.

The finial layout, including doors, windows, pillars and luminaires.

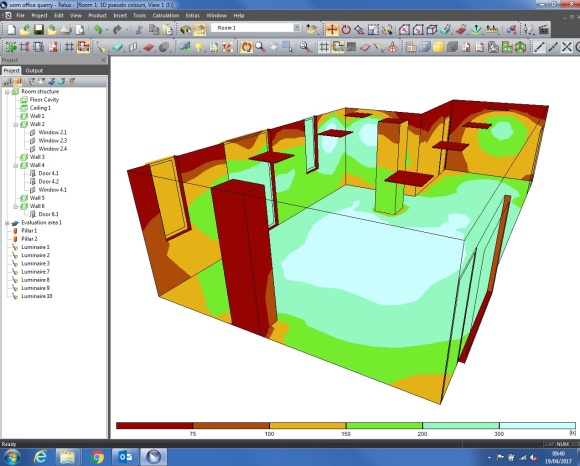

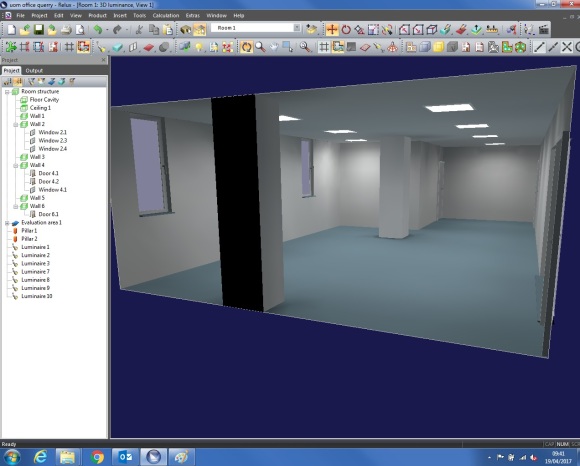

Once our luminaires are placed and we are happy with our layout, we can run the lighting calculation to see whether the room is lit sufficiently. Relux is able to display calculation results in numerous formats, including 3D views simulating the lighting within the room. A false colour view enables us to see what parts of the room are well lit (coloured green) and what parts of the room are dark (red areas).

False colour plot of the lighting levels. The floor of the room is well lit, whilst the corners are dimmer.

3D room simulation.

We can see that our layout lights the room to a sufficient level, well above the 300 lux required. If this wasn’t the case, we can simply return to our layout view and either reposition the luminaires or add more, and re-run the calculation.